Trackware Product-ID

Trackware focuses on Indoor Asset Management solutions. Trackware develops and produces Trackware TW® Tracking & Tracing products in-house in combination with – state of the art – RFID technology. Trackware TW® products have been developed on the basis of LF, HF and UHF technology without battery power (Passive systems). The current location and specific measurement data are processed, managed and presented in Trackware’s own unique software platform.

RFID components and technology

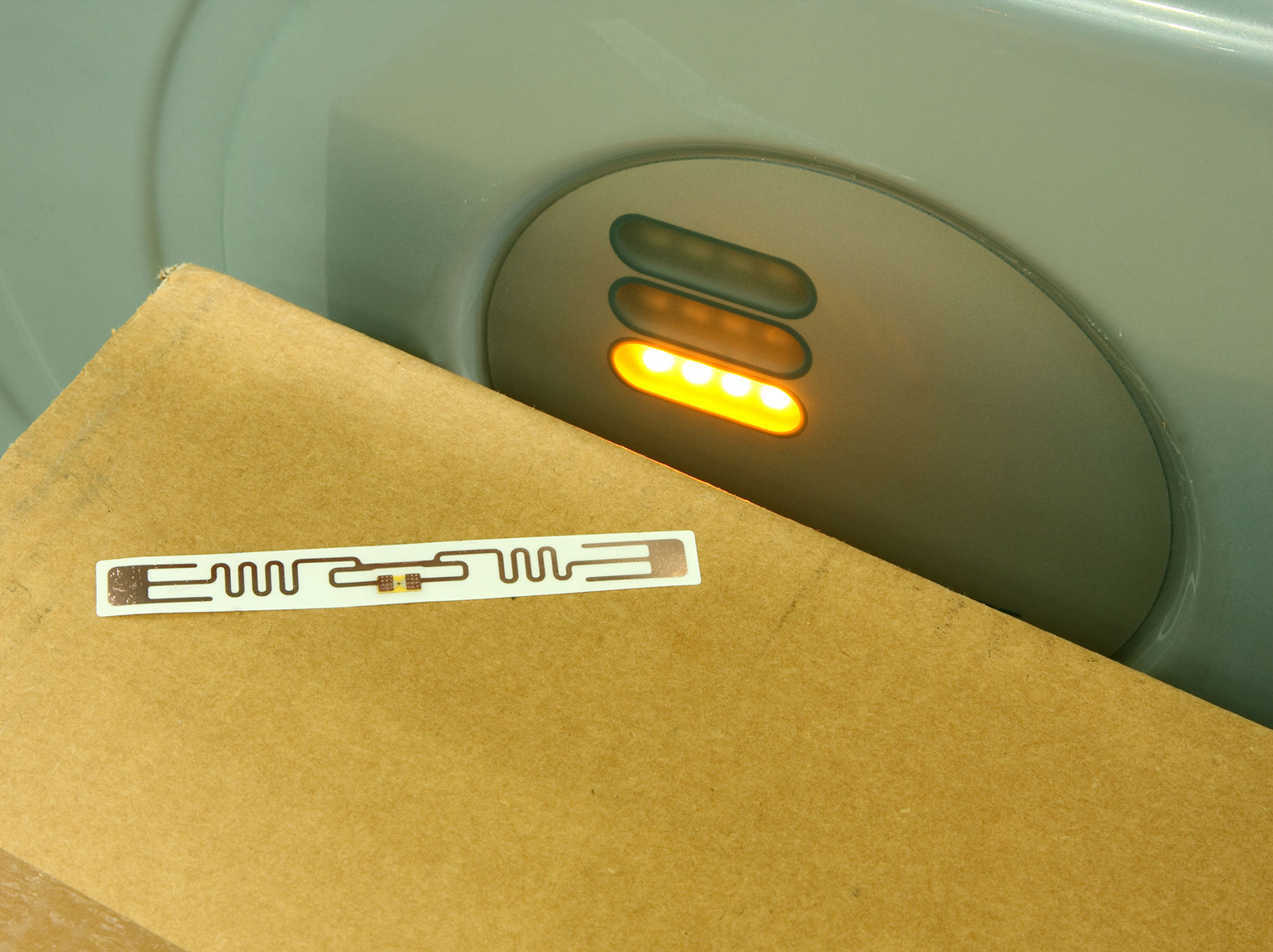

Radio Frequency IDentification (RFID) is a technology to read unique stored product information remotely and contactlessly from so-called RFID tags that are attached to or in objects. Trackware deals exclusively with Passive RFID technology.

Passive RFID tags do not have their own energy source (battery): they use the electromagnetic field of a reader to induce a current in the tag coil that powers the chip. The reader transmits radio waves in the frequency bands LF, HF or UHF.

LF or Low Frequency is an extremely reliable solution but can only bridge a very short distance and transfer relatively little data. LF is insensitive to moisture, water (moisture and water “absorb” radio waves) and metal parts (metal blocks radio waves of some frequencies) and can be used up to a distance of about 10 centimeters. Due to its insensitivity to moisture and water, this technique is very suitable for moisture-containing products in the fruit, vegetable and animal processing industry. This technique is the most common and there are many types of tags available.

HF or High Frequency is also insensitive to moisture and water but not to metal. Metal blocks the radio waves. With HF, large amounts of data can be transferred quickly. HF is also known from the NFC technology for payment cards and public transport cards.

UHF or Ultra High Frequency mainly has the advantage of the relatively very long reading distance without using battery power in the tag. This technique can bridge up to approximately 12 meters in the free field, with the advantages of HF. Because UHF technology has become increasingly reliable in recent years, the market for this is growing rapidly. The disadvantage of this technique is the moisture and metal sensitivity that form a barrier to the radio waves.

For the above RFID techniques and depending on the application, Trackware uses specific tags that can be fully integrated into your products or packaging.

Application

RFID tracking is used in more and more industries to automate and monitor processes. The automatic recognition and tracing of products by RFID tags (transmitters) and readers (receivers) makes the process more efficient and safer in difficult and dangerous conditions.

Important advantages of RFID over barcode technology:

• automatic reading;

• read through the package;

• read several hundreds of tags in seconds;

• carry more data per product;

• current status (T, RH, etc.);

• environment dirty or dangerous;

• temperature- (280 C) and pressure (30T) resistant ;

• liquid, dust and moisture resistant;

• durable, no damage;

• create almost any tag shape;

• can be integrated into product;

Because much more data is and remains available during the useful life of a product, unprecedented new uses and business models are also emerging. This includes shelf life of food, signaling defects, monitoring maintenance intervals and repeated sorting and separation in cycle processes.

Tags come in many forms. Examples are: sticker, (glass) capsule, adhesive strip, ear tag, tie wraps, key ring, card (mifare card), wrapping tape, etc.

Trackware uses RFID equipment of the following mail brands:

- AXEM

- Balluff

- Datamars

- iDTRONIC

- Kathrein

- Zebra (ex Motorola)